Have you ever asked for a quote on a [silicone mold](https://www.aeromarineproducts.com/different-types-common-molds/?srsltid=AfmBOora7jKADg9dF-4XS3Hj0CLssNA8No3JJHKiwP4CLO23xVkXRpWu), only to receive wildly different prices? This can be confusing. The problem is that “silicone mold” has two completely different meanings.

A custom silicone mold can cost anywhere from a few dollars to over one hundred fifty thousand dollars. The huge price gap exists because “[silicone mold](https://www.aeromarineproducts.com/different-types-common-molds/?srsltid=AfmBOora7jKADg9dF-4XS3Hj0CLssNA8No3JJHKiwP4CLO23xVkXRpWu)” can mean a cheap mold made *of* silicone (like a cake mold) or an expensive steel tool used *to produce* silicone products.

s](https://samxine.com/wp-content/uploads/2025/10/silicone-mold.jpg”)

In my fifteen years in the silicone industry, I’ve found this is the biggest source of confusion. Many people think these two things are the same, but their costs and uses are worlds apart. Before you spend any money, we need to figure out which type of mold you actually need. Getting this right will save you a lot of time and money.

## Which “Silicone Mold” Are You Actually Talking About?

Are you trying to make a simple cake mold but receiving quotes fit for an industrial project? This misunderstanding is common, wasting both your time and budget. Don’t worry, the two types of “silicone molds” are entirely different, and I’ll help you distinguish them to get your project back on track.

Simply put, there are two kinds of “[silicone mold](https://www.aeromarineproducts.com/different-types-common-molds/?srsltid=AfmBOora7jKADg9dF-4XS3Hj0CLssNA8No3JJHKiwP4CLO23xVkXRpWu)s.” The first kind is a mold that is itself made from silicone material, like a cake mold or an ice cube tray. The second is a metal tool used to produce silicone products, made from materials like steel or aluminum.

When I first started in this business, I often got these two concepts mixed up myself. As I worked on more projects, I began to understand their fundamental differences. Here at Dibo Tech, when we talk about a “[silicone mold](https://www.aeromarineproducts.com/different-types-common-molds/?srsltid=AfmBOora7jKADg9dF-4XS3Hj0CLssNA8No3JJHKiwP4CLO23xVkXRpWu),” we are always referring to the second type—the precision tool known as the “mother of molds,” which is used to manufacture thousands or millions of silicone products.

### Type 1: Molds *Made Of* Silicone

이 몰드는 실리콘 재질로 만들어집니다. 유연하고 저렴하며 일반적으로 실온이나 저열에서 케이크를 굽거나 초콜릿을 만들거나 집에서 DIY 비누를 만드는 등의 용도로 사용됩니다. 비용은 주로 재료, 가공을 위한 소량, 브랜드 마크업으로 구성됩니다.

### Type 2: Molds *For Making* Silicone Products

This is a true piece of industrial equipment. It’s made from hard metals like P20 or S136 steel, or aluminum. We use it in processes like compression molding or [injection molding](https://www.youtube.com/watch?v=B1xwun0P5LI) to mass-produce silicone keypads, seals, medical components, and more. Its value lies in its precision, durability, and engineering.

To help you see the difference more clearly, I’ve created a simple comparison table:

| Feature | Type 1 (Mold made of silicone) | Type 2 (Mold for making silicone) |

| :— | :— | :— |

| **Material** | Silicone | Steel, Aluminum, Copper |

| **Primary Use** | Baking cakes, making ice, DIY crafts | Mass-producing industrial or consumer silicone parts |

| **Overall Cost** | Very low ($10 – $100) | Very high ($1,000 – $150,000+) |

| **Technical Skill** | Low | High, requires precision engineering and machining |

| **Industry Term** | Cake Mold, Ice Tray, DIY Mold | Production Mold, Tooling, Steel Mold |

## Why Are Steel Production Molds So Expensive?

Does it seem unbelievable when you see a price tag of tens of thousands of dollars for a mold that makes a palm-sized silicone part? This stark price contrast can stop many projects in their tracks. But this cost isn’t arbitrary; it covers three core elements: material, machining, and expertise. Let me break it down for you.

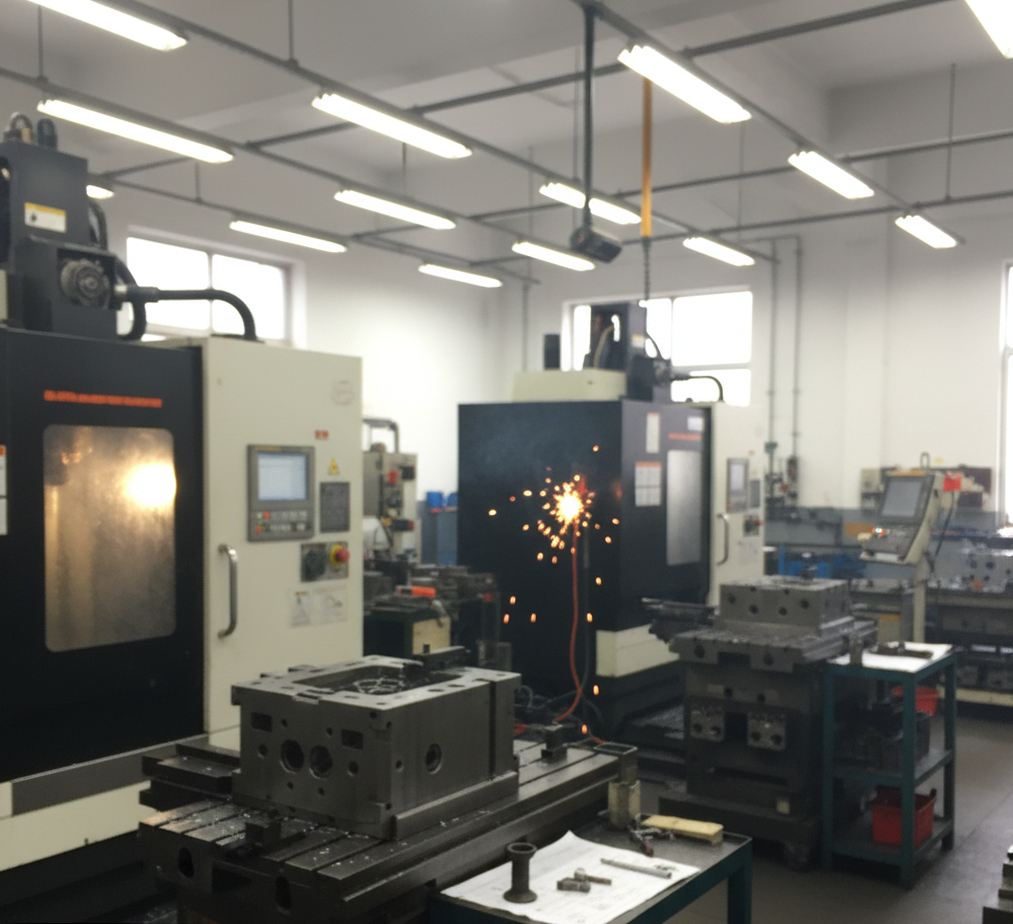

The high cost of a production mold is not just about the metal. More importantly, it includes complex processes like CNC machining, [EDM](https://en.wikipedia.org/wiki/Electrical_discharge_machining), and grinding, combined with the intellectual investment of designers and engineers. This is how a simple block of steel is given immense value.

Imagine a plain block of iron. By itself, it might only be worth a few dozen dollars. But to transform it into a precision tool capable of producing tens of thousands of identical silicone parts with flawless accuracy, it must go through a “forging” process. The cost of this process far exceeds the cost of the raw material itself.

### First, the Material Cost

일부 특수 실리콘은 매우 비쌀 수 있지만, 몰드에 사용되는 고품질 강철(예: 킬로그램당 $2-10)은 일반적으로 표준 실리콘 고무(킬로그램당 $2-5)보다 더 비쌉니다. 하나의 몰드 무게가 수백 킬로그램에 달할 수 있으므로 재료비만 해도 상당합니다.

### Second, the Complex Machining Costs

This is the biggest part of the mold’s price. That “bare block of iron” must be precisely shaped by CNC (Computer Numerical Control) machines, detailed with EDM (Electrical Discharge Machining), and polished to a mirror finish by grinding machines. This equipment is expensive to own and operate, requires highly skilled technicians, and consumes a lot of time and energy. These are all real, tangible costs.

### Finally, the Intangible Cost of Expertise

This is often the most valuable part of the mold. An engineer must design the mold’s runner systems, venting, and ejection mechanisms based on your product’s design. The quality of this engineering directly impacts production efficiency and product quality. This is the crystallization of years of experience and technical knowledge, which cannot be measured in simple man-hours.

이 표는 비용 내역을 설명하는 데 도움이 됩니다:

| Cost Component | Description | Impact on Price |

| :— | :— | :— |

| **Material Costs** | The cost of the mold steel, mold base, and other hardware. | This is the base cost but usually not the largest portion. |

| **Machining Costs**| The time, tool wear, and energy used by CNC, [EDM](https://en.wikipedia.org/wiki/Electrical_discharge_machining), etc. | The core of the cost. More complex parts require more machining. |

| **Design & Debugging** | Engineering, programming, assembly, and iterative testing. | The intangible value that determines the mold’s precision and lifespan. |

So, when you pay up to $150,000 for a [silicone mold](https://www.aeromarineproducts.com/different-types-common-molds/?srsltid=AfmBOora7jKADg9dF-4XS3Hj0CLssNA8No3JJHKiwP4CLO23xVkXRpWu), you’re not just buying a block of steel. You’re investing in the collective expertise, technology, and experience of an entire team.

## Conclusion

In summary, there is no single answer to the question, “How much does a custom silicone mold cost?”

핵심은 먼저 DIY 프로젝트를 위한 저렴한 실리콘 기반 몰드인지, 대량 생산을 위한 산업 등급의 정밀 가공된 강철 몰드인지 파악하는 것입니다. 후자는 값비싼 재료, 복잡한 제조 공정, 귀중한 기술 전문 지식이 반영된 비용으로 중요한 산업 자산입니다.

At Dibo Tech, we specialize in the latter—developing high-quality, efficient production molds for our clients’ silicone products. Having been in this industry for fifteen years, I know how critical a good mold is to the success of a product. If you are looking for a reliable molding solution for your silicone product or need a clear, transparent quote, I would be happy to help you with my experience. Let’s work together to bring your idea to life.